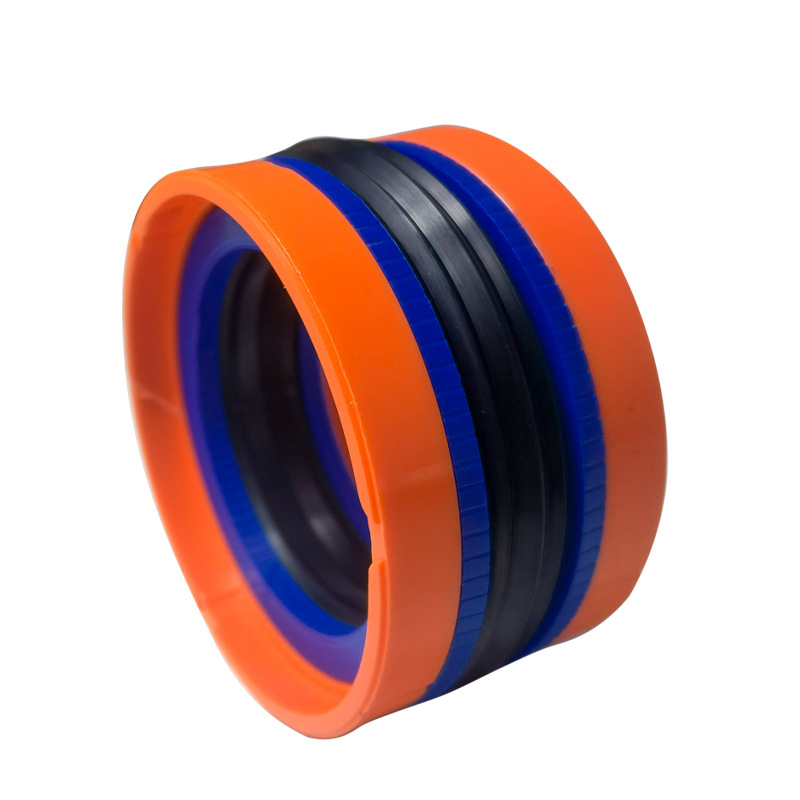

KDAS five-piece oil seal hydraulic cylinder piston rod hole with five-piece seal ring TPM injection molding machine 55-95.

Specification Details of KDAS style oil seal.

KDAS is a double-acting combination seal, which consists of three parts: an elastic seal A, two support rings B, and two guide rings C.

The elastic seal A has a special section with three sealing lips against the cylinder wall (dynamic seal). The middle lip is thicker. And the middle lip acts as the main seal. The other two lips act as auxiliary seals. The bottom side is in close contact with the bottom of the piston groove (static seal). The contact is larger than the aforementioned three lips.

The support ring B is placed on both sides of A for positioning. Supports the elastic seal A and prevents A radial seal gap. The support ring B is stepped. And the side in contact with the sealing element has many bumps to prevent the sealing ring from rotating during operation.

The guide ring C is rectangular and installed on the piston to guide and absorb the axial force. Several axial grooves are opened up and down the guide ring. So that the pressure oil can pass through the guide ring. The elastic seal A can feel all the working pressure. And seal A quickly release the pressure when changing directions. This prevents sustained overpressure.

The hardness of the material gradually increases from the inside to the outside, and according to its characteristics, it plays the role of sealing, supporting and guiding respectively.

For self-tightening double-acting seals. KDAS five-piece oil seal. In the initial state, the elastic seal A is deformed to generate a radial preload. seal A increases with the increase of the system pressure, so as to generate a complete sealing force, which can play a sealing effect even if the system has no pressure.